EPLAN Harness proD

Cabling in 3D

Use EPLAN Harness proD to efficiently design and document your cabling on 3D mechanical models – the software allows you to combine your mechanical and electrotechnical designs. Optimise and digitalise typical cabling workflows, including documentation for preconfigured cable assembly.

EPLAN Harness proD for Your Areas of Application

Discover EPLAN Harness proD’s many varied application fields – including for your industry and engineering disciplines.

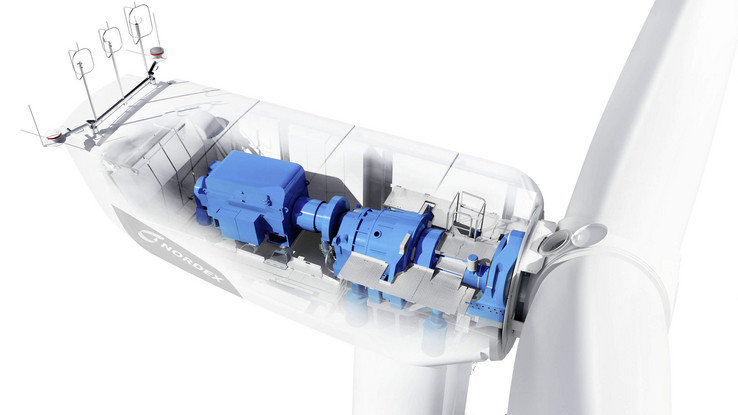

EPLAN Harness proD for Designing Wire Harness using the Digital Twin

With EPLAN Harness proD, you can enhance the digital twin with the relevant electrical engineering information early in the engineering process. This means the cabling and wire harness designs don’t depend on the availability of a mechanical prototype. The software is open to MCAD systems and can be seamlessly integrated into existing system landscapes.

The intuitive 3D environment makes it easy for you to design cabling and wire harnesses.

You define the routing paths and the automated routing of wires and cables.

The required manufacturing documentation can be created automatically, saving you time and increasing the quality of your documentation.

With the EPLAN Harness proD API development environment the doors to your individual further development are wide open. The development environment offers you an efficient possibility to implement your own required functionalities or automatic functions. With this individual customization in the core of EPLAN Harness proD you can optimize your engineering workflow specifically.

Faster task-based processes

Use of the overall solution is thus facilitated for all participants. Processing times, planning errors and training times can be reduced. Results are thus available faster and more economically.

EPLAN Tutorials

Moving images explain things better! That’s why we’re providing free of charge tutorials that support you in the daily use of our solutions.

System Requirements

What hardware and software requirements should your system meet for the use of the EPLAN Platform?

Highlights around the current release

Get an overview of innovative functionalities that make your project planning more efficient.

We’re Here for You!

EPLAN offers you comprehensive services and support beyond our software. We’re looking forward to supporting you!

EPLAN Harness proD in Practice

Learn from first-hand experience about how our customers and partners benefit from EPLAN Harness proD when creating cabling and wire harnesses and assembling digital twins.

The Digital Twin and Designing Wire Harnesses

Gartner says it. Deloitte says it. EPLAN says it, too: the digital twin is becoming the driving force of industrial production in the twenty-first century. Embedded into the megatrends of Industry 4.0 and the Industrial Internet of Things, the digital twin brings manufacturing companies significant advantages across the entire product life cycle.

We’re Happy to Help!

Please contact us if you’d like to learn more about our solutions. We’re looking forward to helping you.