Discovering the wow factor in EPLAN

The staff at WOW Company are proud of its name and what it represents: a spontaneous reaction of satisfaction and amazement. That pretty much sums up their experience with EPLAN software.

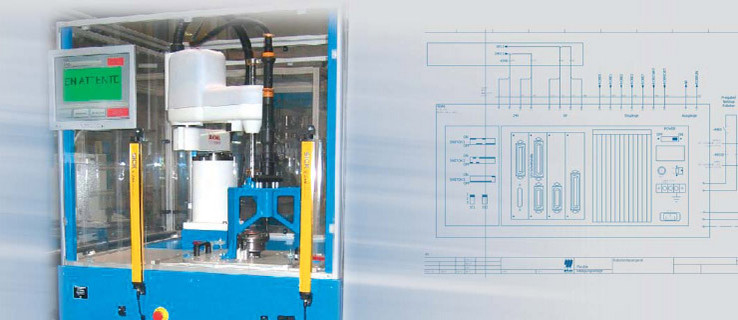

The staff at WOW Company are proud of its name and what it represents: a spontaneous reaction of satisfaction and amazement. That pretty much sums up their experience with EPLAN software. The enthusiasm is palpable. The Belgian firm was once mainly known for producing the Wave Ball, a motorized, floating wave-making device that livens up swimming pools in 30 countries. It still makes and sells them. But over the years, WOW has diversified into industry, performing custom design and installations for robot cells, production, assembly and benchmarking equipment. One customer needs an automated packaging line with pick and place cells that can place 300 products a minute in blister packs. Another needs a robot that will shift newly formed windshields off the assembly line and put them on storage racks when the line stops. ”Our old CAE system wasn’t living up to our expectations. We discovered problems that mainly related to the stability of the system, which resulted in information sometimes being lost or having tables generated that were inaccurate. Now with EPLAN, it’s terrific to be able to count on a reliable system! No information is being lost and all the tables being generated are correct. For a time after the switch, we still double-checked everything, looking for errors. Force of habit. Now we don’t bother. We know we can work with confidence. That represents an unbelievable saving of time.” (WOW Company spokesman Philippe Hermant) Productivity enhancing features

WOW Company undertakes an various mix of projects that’s sort of wow! in itself and demands a stable and fully featured engineering design platform like EPLAN Electric P8. Don’t underestimate the simple comfort of being able to take for granted the stability and accuracy of a CAE system. The stability of EPLAN Electric P8 was one of the first wow factors WOW engineers experienced once the company switched over. EPLAN delivers great stability, accuracy and capacity whatever the size of a project, and that doesn’t diminish as a company’s business becomes larger or the assignments more complex. As was the case with WOW, many companies are driven to choose EPLAN in part because their previous CAE software was no longer capable of handling the job or workload a company was undertaking. Even before they come to appreciate all of EPLAN’s many productivity enhancing features, new customers feel liberated by EPLAN’s reliability. Quality and accuracy absolutely critical

With over 40 employees now, WOW Company does its own research and design and has a cabling and processing department and another for mechanical welding and assembly. If there is one thing WOW stakes its reputation on, it’s being accurate, precise and on time in all of its project work and commitments. WOW’s project staff covers four disciplines – electromechanical, electrical, electronic and IT. The company, which partners with leading manufacturers of automation equipment like Siemens, Kuka, Epson, ABB and National Instruments, has undertaken a wide range of turnkey projects. Something as straightforward as an automated dispenser of oxygen absorbers – the little pads that go into food and pharmaceutical packaging – involves a great deal of engineering. The designer has to integrate a linear conveyor, air lock chamber, vibrating bowl, optical detector that pilots an air ejector and twin axis manipulator. Each pad has to go print side up, hence the optical detector and air ejector; any pads on the conveyor print side down are ejected. Even more engineering work went into a robot cell WOW designed and delivered to AGC Automotive in Russia to handle newly formed windshields coming out of the bending oven. The centerpiece of the cell is a Kuka robot, but the complete cell includes seven belt conveyors, a glass rotating system, an adjustable squaring system for precision positioning, a rotating “PEG”, two rotating storage units, one inspection unit and a safety fence. The project included the integration of hardware and software along with the integration of the completed cell with the upstream and downstream production processes. EPLAN enjoys widespread third-party recognition, support

Another benefit for WOW of using EPLAN Electric P8 – WOW also uses EPLAN FLUID – is that they’re now on an industry reference program recognized by most suppliers and customers and strongly supported by EPLAN NV/SA in Lummen, Belgium. Working from the EPLAN interface, users can access third party systems and catalogues like that of FESTO and incorporate component data or schematics right into a project. Aftersales service was critical for WOW, not just for the quality of initial training and follow-up help desk support, but for recognizing how to make better use of EPLAN’s rich menu of standard features and optional add-ons. EPLAN Electric P8 is the first EPLAN electrical design software that allows different users to have simultaneous access to a project and instantly view changes made by the others in real time, which is collaborative engineering at its best. The user interface (toolbars, icons, tool tips, keyboard shortcuts and workspaces) can be customized. Users can create and edit templates, create macros for documentation and management of macro libraries, configure the desktop, graphics editor, schematic page settings, contact image displays as well as list- and tree-view display settings. ”The experts from EPLAN think together with us, make proposals and always respond to our needs. They take our comments and suggestions into account when developing new CAE software. It’s a relationship that can only get better and better, and it makes EPLAN a preferred partner for us.” (WOW spokesman Philippe Hermant) Satisfaction is never having to worry about accuracy

Switching to EPLAN software brought large benefits for WOW Company engineers even before they had a chance to learn about all of its advanced features. The stability of the platform and accuracy of the output was something that they hadn’t had the luxury of enjoying with their previous design software. Not having to doublecheck all their finished work for errors brought a significant productivity boost, as did automating many functions and the simplicity of working in a familiar, userconfigurable interface on industry standard software. A great number of tasks which were being performed manually with the previous software now were automated. Moving to EPLAN was just the beginning of the relationship between the two companies. Find out more about WOW Company on <link http: www.wowcompany.com>www.wowcompany.com.