Switching over to the right track

Complicated products and processes. Lack of technical personnel. Increasing competition. These were the main challenges Terberg was facing some years ago.

Complicated products and processes. Lack of technical personnel. Increasing competition. These were the main challenges the Dutch company Terberg Control Systems was facing some years ago. To get a clear future vision the company invited various partners for brainstorming sessions. Today the specialist in controls for complex Caterpillar generators supplies more and better products with fewer specialist personnel, due to the fact that the high level of knowledge has been anchored in the EPLAN Platform. In addition, EPLAN Pro Panel Professional has been launched to achieve large-scale automation of the production of switch consoles. Complex systems easily controlled

Terberg Control Systems in IJsselstein originated in the 1940s. The company started out selling washing machines, and quickly grew to become a multifaceted fitting contractor. The installation of systems for swimming pools and combined heat and power plants led to the addition of enclosure construction. Terberg got into generators around 20 years ago. The control systems developed by the company for the generators of Caterpillar Power Systems stand out for their simplicity for the user, despite the fact that they are capable of controlling extremely large and complex systems of up to 250 MW. Challenges efficiently mastered

Around 10 years ago, Terberg foresaw an increase in competition from Asia. They weren't better at development, but they were cheaper at building enclosures. “It was getting harder and harder to find technical staff,“ says Erwin Althof, manager of the hardware department at Terberg Control Systems. “As a lot of knowledge is required for our products, getting an enclosure builder up to speed took us half a year, and an engineer, a year. That had to change.” Terberg invited various partners – including EPLAN – to think about a solution. The result was a clear future vision: making products and processes simpler in all aspects. The first step was taken in sales. The product was cut up into standard modules. Using a handy sales tool, the sales staff can now put together a custom product from modules. Althof: “This resulted in a huge efficiency improvement. With a single mouse click, the salesperson creates a quotation, including technical descriptions. This ensures that the customer sees exactly what he is getting. If the order goes ahead, the engineer fills in the technical details, on the basis of the same data set. Customer-specific custom work is kept to a minimum.“ One step ahead: CAM

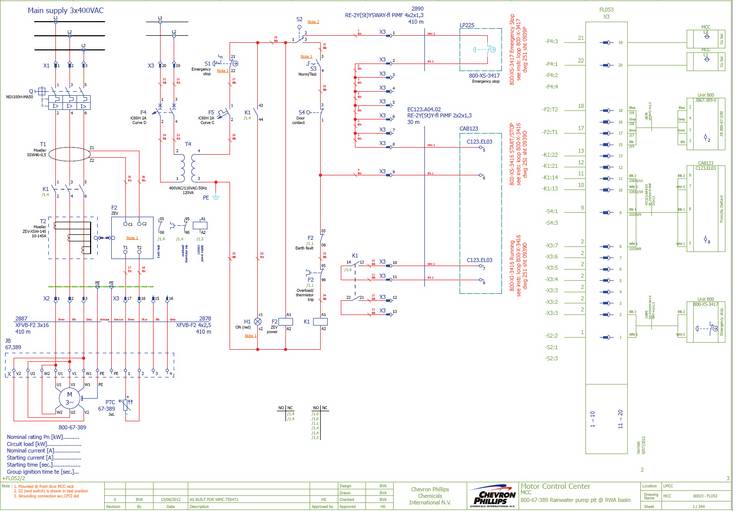

Terberg went further and connected the system to the machines for the custom manufacture of boards, wiring and labels. The entire logistics process was then connected to the system. The objective was to achieve error-free and lean production.These last steps made Terberg one of the first enclosure manufacturers to use Computer Aided Manufacturing in practice. The direct connection with production is made possible via EPLAN Pro Panel Professional in combination with EPLAN Electric P8. Less knowledge on the shop floor

“We have shifted the knowledge from the people to the system,“ Althof explains. “Everything now comes from EPLAN: from the instructions for the CNC machines through to the work instructions for the enclosure builder. This person no longer has to deal with a thick book, they just get a single set of instructions for each action. The wires are automatically custom-produced and labelled. The whole process ensures that we supply an error-free product.“ Top efficiency and turnover

Thanks to this standardisation using EPLAN, Terberg has also removed a great deal of repetitive work from the engineering process. Althof: “We have now anchored a wealth of knowledge in the system. This saves our engineers a great deal of time. In 2001, we produced 40 control units per year. This has increased to 720 this year – with the same team of eight people! As a result, Terberg has experienced huge turnover growth during the past 10 years. This indicates that a high degree of automation does enable you to produce competitively in Europe. It is the solution.” Long-term partnership

The engineering team at Terberg have been working with EPLAN software since the 1990s. “The software has become much more for us than just a handy drawing program; EPLAN forms the heart of our engineering,” says Althof. “In addition EPLAN played a role as a sparring partner in this entire efficiency improvement process,” he continues. “They brainstormed with us, suggested alternatives, took care of the implementation and provided live instruction to our engineers in IJsselstein. EPLAN is more than just a supplier; they taught us how to engineer as optimally as possible.” Result: Staying on course!