Wind in your sails

Aurich company Rolf Janssen GmbH uses EPLAN Electric P8 for constructing energy distribution systems and automation and process control systems.

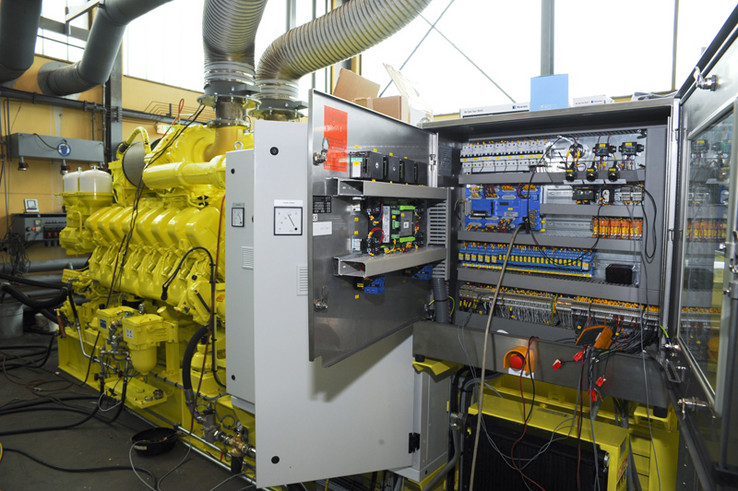

EPLAN Electric P8 as a strategic and efficient CAE tool in switchgear construction: Among other things, Aurich company Rolf Janssen GmbH uses the database-orientated engineering tool for constructing energy distribution systems and automation and process control systems. Another main focus is supplying the electrical equipment for ships. The company is also currently working on the introduction of EPLAN PPE and EPLAN P&ID within the scope of customer orders. The goal: continuous optimisation of production processes by means of automation – provided that this results in improved efficiency and a competitive advantage.

The breeze has always been somewhat stiffer in the north than the south of the republic. The fact that wind connects is particularly evident in East Frisia. Instead of bending over into the headwind, we link arms and set off in a new direction together. This creates a tailwind for new projects and a high pressure area for innovation in maritime systems engineering, amongst other things. After all, more than 1600 ships on the seven seas carry Rolf Janssen technology on board, including a large quantity of high-tech cruise ships from a well-known shipyard in neighbouring Papenburg. Less glamorous, but no less high-tech, are the control systems on the so-called LNG tankers. They transport liquid natural gas safely around the globe in distinctive steel tanks. From light and energy distribution, switchgear for traction motors to entire onboard power systems, the Janssen group of companies, which was established in 1949, has a good reputation and can demonstrate considerable expertise in the areas of energy engineering and automation and process control systems in usage areas on the mainland. Modern database solution

When Janssen decided to replace the existing CAD system with a modern database system, "we looked for a solution with which we could draw quickly and easily, and also deal with very large projects in an extremely structured way," reflects Achim Corsten, head of the automation and process control system department. "EPLAN is the market leader. At the time it was definitely a decision-making argument, whereby P8 provided a considerable amount of flexibility within structured working methods." Whereas the D literally used to mean Design in everyday practice, the E in modern CAE systems approximates to Engineering. Corsten: "Thanks to a company-wide product database we can attach a great deal of additional information to an icon." Since the early days of pure CAD drawing it has become proper engineering, accompanied by standardised processes. The way in which work is carried out in a standardised way at Rolf Janssen GmbH is described in detail in the planning guideline, which was developed together with EPLAN during the introduction of P8. It is obligatory reading for all employees who produce electronic documentation. The aim of the continuously updated manual is to clearly define the workflow that is needed for the construction processes. The effective interaction of all employees and departments involved in the construction process is only possible with this definition of company-wide principles, which provides efficient, reproducible processing with a high degree of productivity and quality.

For example, if a new project is created, the copying of basic project data from existing projects must be avoided, which is contrary to the widespread practice. Forms and symbols are two good examples. At the end of the day, only working with valid project data really ensures that all company-wide current settings are brought to bear. Recurring circuit diagram typicals and symbol macros for project planning with EPLAN Electric P8 are maintained company-wide and made available to all users using the modular principle. Part lists, ready to orderAt this point Corsten emphasises that Janssen's ERP system (b2 from Sage Bäurer), generates complete, ready-to-order part lists from the P8 circuit diagrams. For this purpose, EPLAN has programmed an individual interface during the scope of software integration at Rolf Janssen GmbH. "We integrate the CAE system seamlessly into our company-wide resource planning – from purchasing to warehouse logistics, all the way to delivery." Another interface is used to link the company to switch cabinet construction. The designers "feed" the company’s internal sheet metal processing with all dimensions for the edges, holes and punching from EPLAN Electric P8. On the one hand, the high manufacturing depth is needed to manufacture unique, made to measure switchboards or consoles, and on the other hand it has led to standardised in-house development. The company has been successful with the TopDraw plug-in module system for energy distribution systems. Customers from different industries appreciate the top quality workmanship and innovative technology. "The automated interfaces are precisely what we need because we produce in large quantities," says Corsten. How is the north German engineering company and its 400 or so employees going to develop? The answer is simple: “More automation will make us more effective.” EPLAN Electric P8 is already importing Microsoft Excel spreadsheets into the engineering environment via the API interface. The first circuit diagrams for the respective orders are then automatically created from these basic lists.