Electrical planning by means of configuration

A configuration tool for electrical engineering planning based on the EPLAN Engineering Center allows increasingly complex electrical engineering to be created on a largely automated basis.

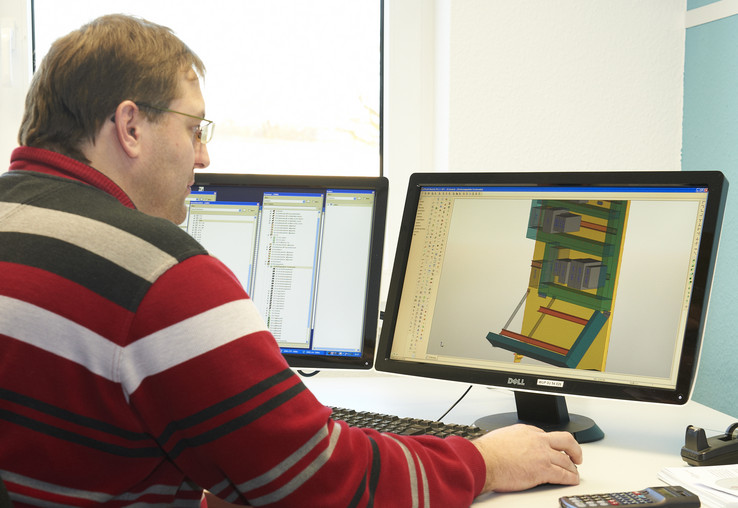

New engineering methods are opening up a new area of business for Ripploh Elektrotechnik GmbH - building technology. A configuration tool for electrical engineering planning based on the EPLAN Engineering Center allows increasingly complex electrical engineering to be created on a largely automated basis and also counters the 'fierce' pressure on costs and time in this sector. The principle of assembly-based engineering can be further carried and transferred to mechanical or plant engineering. Ripploh Eletrotechnik GmbH is well established as a service provider for mechanical and plant engineering inWestphalia, Germany. The company plans the complete electrical engineering equipment for machines and converts the plans within its own enclosure construction division. The fact that Ripploh works with state-of-the-art methods and is welcoming of automation was made clear in its decision to become one of the first users of the EPLAN Engineering Center (EEC) in 2007. Since then, its customers have been able to benefit from completely consistent enclosure construction. From order placement and materials management through electronic design with EPLAN Electric P8 to automated sheet metal processing and cable fabrication, every step of the process is integrated and consistent. This leads to very short throughput times and competitive pricing despite the high level of quality. Huge pressure on time and costs A meeting between the managing director and shareholder Dipl.-Ing Andreas Ripploh and a new customer from the building automation sector led to the company starting to tap into this new business field around two years ago: "The technology for public or commercial buildings is becoming increasingly complex, with various elements to be planned, including heating, air-conditioning/ventilation, solar power systems and electrical installations. Even medium-sized properties incorporate ten to twenty enclosures and the pressure on both time and prices is considerably higher than in the mechanical and plant engineering sectors." Given these conditions, Andreas Ripploh was wondering how the construction technology market could be tapped into without compromising on quality. The answer came, once again, in the form of consistent automation. Construction assembly based on 760 modules Unlike in the established area of business, where the module system could gradually be switched over to EEC, intensive preliminary work needed to be done here. Andreas Ripploh: "We analysed the customer's projects and defined 760 assemblies from a selection of several thousand construction modules. We saved these assemblies in EEC." Based on these modules, Ripploh developed a configuration tool for its customers - a user interface which guided them through the project so that all the relevant data was available by the end. This tool is not only used at the planning phase, but also considerably earlier. Andreas Ripploh: "Even quotations are processed in the configuration tool. The planner puts the necessary modules together and adds the relevant parameters, such as power ratings. As the price including assembly costs is saved for every module, our customer can cite a binding price at an early stage - and we have a contractual obligation to build the enclosure for this price." From the configuration tool to ECAD and ERP If the order is placed, the planner sends the relevant configuration to Ripploh, which carries out a brief feasibility check before starting on the detailed planning and production. Within 24 hours, the schematic is available with more information than before from the outset. Andreas Ripploh: "The schematics for the function groups are automatically output in EPLAN Electric P8 and EPLAN Pro Panel. And as the EEC is also connected to our ERP system ABS, the bill of materials is also available immediately and we can order any missing components immediately and start planning production." The benefits also include the fact that the set-up drawings are available from the beginning and the enclosure sizes are defined. "This saves us the time-consuming repeat amendment processes," the company boss explains. Forgetfulness is not a problem The control knowledge stored in the configuration tool is based on questions and makes sure that nothing is forgotten. Even details such as the door hinges for the enclosures are defined. The tool provides the planner with the necessary flexibility as they can change an existing module at any time and plan it as a special solution. At the same time, technical details can be saved as text comments. This means that Ripploh's customer can save a great deal of time on planning and can produce a binding quotation in no time. However, the project does require thorough preparation. In close cooperation with its pilot customer in construction engineering, the Ripploh developers invested a total of one man year into the configuration tool. Has this investment paid off from the customer's perspective? Andreas Ripploh: "Absolutely. Planning times are reduced, quotations are more detailed, all the relevant questions have already been addressed when the contract is signed and no further negotiation is required. This also accelerates on-site commissioning. And because only standardised and certified assemblies are used, quality is always consistently high. Potential savings of over 20% Andreas Ripploh believes that working with the configuration tool has resulted in a cost saving on enclosure planning and construction of more than 20% - with guaranteed quality at the same time: "Close cooperation on a technical basis for the configuration tool definitely provides more potential for savings than constantly looking for the supposedly cheapest service provider and constantly changing suppliers." This begs the question: Can the model also be reproduced in other areas? Andreas Ripploh is confident: "Of course. The principle works just as well in mechanical engineering, plant engineering and building automation. In all three areas, module-based engineering has advantages as we are working with modular systems and recurrent tasks. However, the necessary organisational structures do need to be created, and a consistent flow of information based on a development platform such as the EEC is also required."

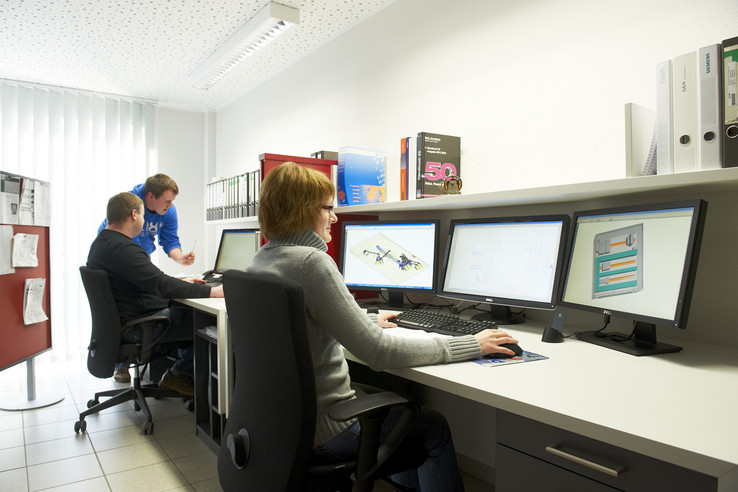

Dipl.-Ing Andreas Ripploh is geared towards consistent automation in both electrical planning and enclosure construction.

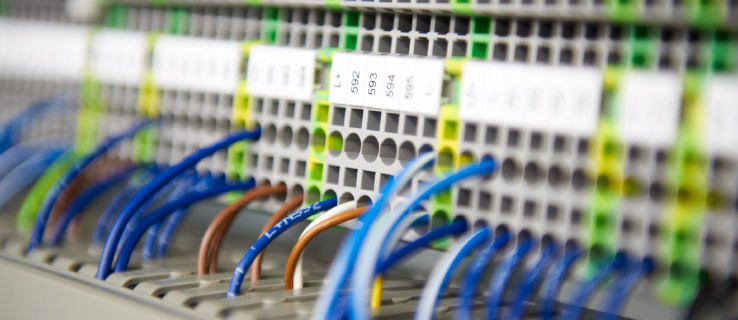

Ripploh Elektrotechnik GmbH configures and builds switchgear systems for industry and, more recently, for building engineering.