New Lachaussée resolutely chooses cutting-edge technology

Some companies simply emanate expertise and know-how: both on a national and an international level. New Lachaussée is one such company.

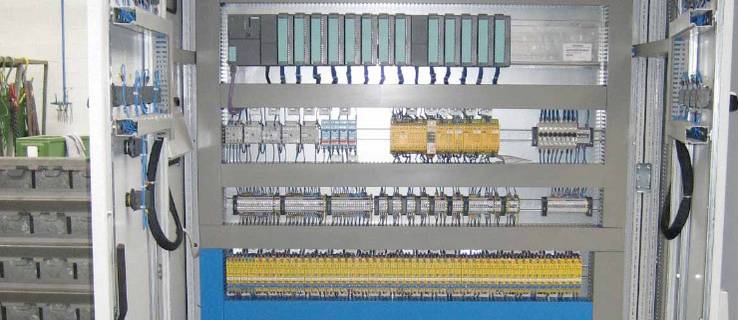

Some companies simply emanate expertise and know-how: both on a national and an international level. New Lachaussée is one such company. The company from Milmort (formerly Herstal) has evolved into a world leader in high-tech production machines and presses for metal components for industrial use and ammunition for hunting, sports, leisure and military applications. Together with their 71 employees, an annual turnover of almost 20 million euros is achieved. A large portion of the turnover is generated by exports, which is clear proof that New Lachaussée has an excellent international reputation. It is no coincidence that New Lachaussée is no. 1 worldwide. The company purposefully invests in cutting-edge technology. The drive for perfection is also evident from its baseline: ‘When good is not good enough’. New Lachaussée is not content with just ‘good’, they aim for the top, for the best, as is apparent from their products and hand-picked suppliers. All this has been done meticulously, to ensure maximum production efficiency. It was from this perspective that New Lachaussée chose EPLAN Electric P8 for the design of its circuit diagrams. ”Our choice of EPLAN is based on objective and well-considered criteria such as return and increased productivity. It was apparent from a market analysis that EPLAN was the most suitable system for achieving increased productivity.” Yves Delmotte, responsible for the electrical department at New Lachaussée. Quality and efficiency

Thanks to the extensive research carried out by its R&D department, New Lachaussée can now easily meet all possible customer requirements. From requests that are easy to fit into a traditional circuit diagram, to special orders that require the existing equipment to be modified. It goes without saying that reliability is a very important aspect of circuit diagrams. Switching to intelligent software Yves Delmotte, responsible for the electrical department at New Lachaussée, states: “In short, our company’s success can be explained by two key elements. In the first place by our drive for quality that has resulted in our ISO 9001:2000 certification. And secondly, we can often make a difference because of the high efficiency of our production. EPLAN also deserves credit for this. The improvement in our productivity was one of the decisive elements for choosing EPLAN. We were using simple drawing software to design our circuit diagrams, so the switch to intelligent software became increasingly urgent, especially since we knew we would benefit in both time and productivity.” Positive market analysis

So New Lachaussée launched a market analysis in order to find the most suitable partner. “We examined the market very thoroughly to see which solution would be the most suitable for us,” explains Yves Delmotte. “The EPLAN systems seemed to meet all our expectations, which is why we decided to take a closer look at other companies that had already been working with EPLAN for some time. They were all fully convinced of the qualities of the system. So our choice is based on objective and well-considered criteria such as return on investment and increased efficiency of our production.” Positive arguments

There were also more practical reasons that played a part in choosing EPLAN, such as its user-friendliness and the extensive EPLAN library. Yves Delmotte: “The convenience and intuitive nature of the interface make it much easier for our engineers to work with this software. And the extensive EPLAN library is a genuine asset. The library contains an increasing number of symbols from other companies and suppliers, which allows us to automatically copy them into our diagrams without the need to first draw them all out.” 50% time savings

After three years, Yves Delmotte has a very clear view of the added value of EPLAN software: “Initially we had just the ‘light’ version of the software, but we very quickly moved to a version with more features. Today we use the EPLAN Electric P8 version and we are very satisfied with it. I think our time savings are about 50% for the complete electrical design of a machine. An exceptional performance thanks to several factors, such as the fact that we make fewer mistakes because the system is completely focused on circuit diagrams. The key to this success? An extremely useful monitoring and analysing tool. Errors are detected in time so we can fix them before production starts. Thanks to EPLAN we have also gained a lot of additional time for wiring and commissioning.“ Investing in cutting-edge technology To a company that attaches so much importance to cutting-edge technology and production efficiency, the time savings that EPLAN software provides are obviously very important. Especially with a view to the international markets, where a short lead time is increasingly necessary in order to win and retain customers. But not only the system itself makes such a difference, the excellent cooperation as a result of working with EPLAN does too. And that results in ... fireworks! Reliable helpdesk

Yves Delmotte: “During the commissioning of the software, we did a course at EPLAN for a few days. It allowed us to discover the most important software features and options. On top of that, we can always count on the professional helpdesk. The EPLAN employees are able to give us systematic and quick answers to all our questions. They are also very efficient in helping us when we encounter problems. As far as the development goes, all users of the new P8 version agree: the user-friendliness and the importance of the new features are unparalleled. In short: EPLAN provides an undeniable amount of added value for New Lachaussée.”