Control Cabinet Planned via the Cloud

EPLAN eVIEW: More Efficient and Paperless Engineering

Panel builder and switchgear system engineering company IWS uses cloud functionality for its electrical engineering. Headquartered in Ichenhausen, Bavaria, the family-owned company with around seventy employees plans, designs and manufactures control cabinets with a focus on specialised control cabinets. EPLAN eVIEW allows the company to share and comment on the status of its projects digitally, securely and transparently. This offers plenty of advantages, both within the company and for collaborating with customers.

High-quality data in engineering and end-to-end digital continuity are important factors for success in panel building and control cabinet engineering. The engineering software EPLAN eVIEW demonstrates the benefits offered by digital processes for making this type of engineering as collaborative as possible and for managing data digitally to the greatest possible extent. With eVIEW, schematics created in EPLAN can be finetuned in the cloud – with co-workers but also across companies, with customers and third-party service providers. Data created and enriched in the platform is provided via the cloud to users – from engineering to manufacturing and assembly, on to service and maintenance. Thus, project data can be viewed and changes can be commented upon from any browser, regardless of location.

Engineering Relocated to the Cloud

Particularly in the course of design services for electrical engineering, but also for manufacturing control cabinets, the new possibilities for communication and cooperation that eVIEW provides are already tangible for IWS. The company’s Design and Sales Director Stefan Glogger explains: “As a service provider, we’re happy when more engineering is relocated to the cloud. It allows us to be more consistent and flexible when working digitally. Customers in the engineering sector who are new to working with us via eVIEW are especially excited about the advantages of these digital working methods.” IWS works with customers via the cloud for the exchange of schematics, acceptances, approvals and comments, eliminating the need to send plans on paper or via PDF back and forth or to coordinate changes.

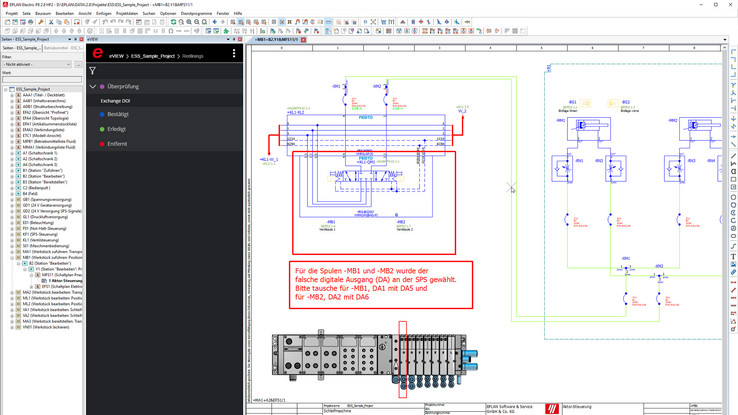

Easy Handling of Reviews

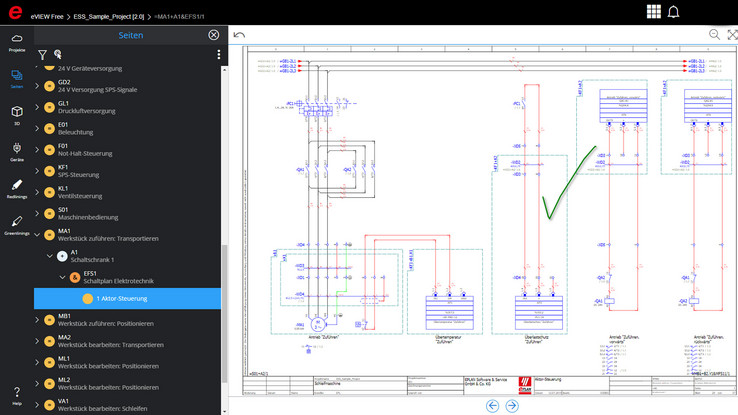

Instead, customers receive a link and work directly in eVIEW, commenting on documentation in the cloud. These comments are then immediately visible to IWS and can be handled directly. Questions can be answered more clearly, more quickly and with more flexibility. “The processing status is always transparent and unambiguous – the latest version, incorporating all the changes, is always there,” Glogger says. “We plan to push this even further so that digital working methods, without paper or PDFs, also become established for our manufacturing processes.” EPLAN Senior Director Cloud Business Software Thomas Michels clearly sees the advantages of cloud-supported working methods: “Often the engineering service providers are the ones who design the control cabinets, for instance on behalf of a machine manufacturer. Over the course of the project, there are repeated reviews, coordination with the customer and status reports. All of these interim statuses in their latest versions can be made available on ePulse so that all participants and stakeholders always have access to the most current and uniform status through eVIEW.” What’s more, all EPLAN cloud applications are grouped together under ePulse. As an individual tool, eVIEW is available for all project participants along the entire value chain as soon as they have registered in the ePulse cloud environment, which runs on Microsoft Azure. The central technical prerequisite is to be using a current version of EPLAN Platform. The eVIEW application can be used starting with Version 2.8, while the most recent Version 2.9 has been available for download since the beginning of 2020.

Well Structured Information Flows

As a service provider, IWS particularly appreciates the so-called greenlining and redlining functions of this engineering tool, which sets up a structured flow of information between participants and allows the designers to maintain control of their schematics and projects. Glogger explains: “With greenlining, only the reviser sees the commentary. With redlining, the design engineer also sees it since a notification becomes visible in EPLAN. The designer can then jump right to the page of the schematics where the comment was made, make changes and then adjust the status accordingly. In turn, an electrical technician can track and understand the changes and adjustments.”

Transparent View of the Cloud Processes

EPLAN wants to ensure transparent data security within the cloud applications with its Trust Center, which is intended to meet industrial requirements at the levels of platform monitoring, threat analysis and incident management. The company says the systems and infrastructure will be continually monitored by a professional team proactively seeking out potential threats. Accordingly, a security operations team will regularly conduct what are known as penetration tests to analyse the security of the company’s own systems and infrastructure, enabling them to recognise potential vulnerabilities at an early stage. Patch management will also be carried out regularly and automatically to enable immediate response to patch updates to minimise the risk of any data loss. In the event of a disruption of service, users will be kept up to date in real time via the Health Dashboard. In addition, ePulse relies on targeted knowledge sharing with industry partners and users for ongoing optimisation of its systems and services.

About IWS

As a service provider in panel building and switchgear systems, IWS designs and manufactures up to 1,200 control cabinets annually, with a focus on specialised control cabinets. About 5 per cent are designed in-house. Customers benefit from certification according to UL508A and also a UL698 Ex approval if needed. Furthermore, IWS can produce in their in-house clean room according to DIN EN ISO 14644 and ISO Class 6 and also offers wire pre-assembly services.

Integrated Control Cabinet Engineering

From individual customers, IWS usually receives completed schematics that have been created with EPLAN in more than half of the cases, plus a complete bill of materials.

Aside from the specification sheet, the control cabinet engineering starts with EPLAN Electric P8 as the ECAD tool. The electrical designs are structured according to functions. The electrical engineering department creates a multi-line circuit diagram where, if possible, everything that belongs to the function is on one circuit diagram page: functional codes are created for the drive or actuator/sensor to which additional parts of the control system belong, such as inputs and outputs, which can be copied more easily later. For maintenance later, this makes it easier to find possible faults since a few clear pages that contain all the information can be used. IWS Design Manger Stefan Glogger explains some of the functional aspects under which schematics can be better configured: “EPLAN is also pushing this working method, because functions can be well structured and managed in macro projects, errors can be corrected centrally and copying from older designs doesn’t take place. Commissioning technicians can get by with fewer schematic pages and use only the function they are working on, simplifying commissioning and troubleshooting.

”Once the schematic is completed and accepted by the customer, IWS uses the labelling export and common labelling systems such as those from Phoenix Contact, Weidmüller or Wago to be able to respond most effectively to customer requirements. IWS is currently planning to bypass text files in the future and to directly write a clip project file that the labeller will only have to import and print.

Faster and More Accurate Designs

IWS creates 3D layout drawings in EPLAN Pro Panel and exports drilling pattern files to program the machining centre, which processes the mechanical control cabinet components fully automatically. Glogger appreciates the software for its “design depth and accuracy, as well as its speed”. The prerequisite for this is that all the necessary data be stored in the database, as Glogger notes: “We also support customers in implementing Pro Panel. The main work is getting their databases up to speed and creating the data they need: drilling patterns and connection diagrams, for instance, so they can route wires and be able to immediately lay them in the digital twin and also output wire sets.”

Data routed in 3D can be imported into the CAD wiring software via a plug-in, for example. “That results in at least 20 per cent time savings for wiring, correct bundling and the use of the appropriate terminal materials,” Glogger says.

As a future trend for assembly – particularly against the backdrop of the shortage of skilled workers – Glogger sees the possibility of using more support staff with tablets and wiring lists, so that specialists can later check the cabinet and do more highly-skilled work when, for instance, “there is less clean routing information”. As Glogger sees it: “Thinking ahead – if you look at the database and where EPLAN is heading with its software – the mounting panels will be wired by robots for production orders,” Glogger says.

Published in Elektro Automation 11/20 (Germany), Konradin Verlag