Future safe building services engineering

Hans Lohr, the Vienna based company, is known as system integrator and provider of complete solutions in the fields of electrical and electronic building services engineering.

Hans Lohr, the Vienna based company, is known as system integrator and provider of complete solutions in the fields of electrical and electronic building services engineering. Electronic planning and design have been done with EPLAN since 1989. The completely switch to EPLAN Electric P8 and its integrated engineering approach has increased efficiency in design and the quality of customer documentation. Plus it facilitates a secure approach towards the future in light of ever increasing demands. You won't always be able to tell right away: Buildings certainly are not just structures of stone, concrete, steel and glass. They are living organisms of electrical and electronic technology. Numerous distributors, criss-crossed with power supply lines, which are more and more used for data exchange between the numerous electrical systems as well; working in companies, offices and buildings or other miscellaneous functions. Challenges in building systems engineering

Ing. Manfred Kulovics knows: "The complexity of technical systems in buildings can be very varied." He is the district manager for instrumentation, steering and control engineering at Hans Lohr GmbH, an Austrian company, founded over 30 years ago, and today a leader in electrical and electronic building system installations. "Their field includes installations for residential buildings to commercial use buildings all the way to hospitals, with most demanding requirements." And the trend is sharply upward, because the goals set for environmental protection can only be realized with energy efficient buildings, which need continuously regulating, comprehensive, and networked monitoring and steering systems to function properly. The need for security technology also continues to rise, like the demand for surveillance technology for managing the rapidly growing IT data volumes. Economist Günter Slabihoud, owner and CEO of Lohr states: "One of the greatest challenges is to make a large number of built-in systems function as simply is possible. Therefore, it is Lohr's philosophy to offer broad support and information to the customer already in the planning stage so that they will be able to secure functionalities across disciplines plus cost optimized implementations." The Vienna company currently has 130 employees and produces annual sales of about 12 million Euros. It offers system integration services for electrical engineering, telecommunication technology, instrumentation, steering & control engineering, as well as security technology, developing a comprehensive and uniform solution, based on the otherwise stand-alone systems of well-known manufacturers. The end result is a high degree of automation, common steering technology, and optimized power consumption, and all with ease of operation. Günter Slabihoud describes Lohr's recipe for success: "We, as a mature company, can ensure carefree operations for our customers, because we perform everything from planning to implementation, continued support and fault elimination services all with our own employees. "This keeps all the knowledge in-house and in one place." The customer appreciates the fact that he has only one contact person, and not only the small and mid-sized customers, but commercial and major public clients as well. Take for instance the City of Vienna; Lohr implemented a building steering system for 200 buildings of the Otto Wagner Clinic, as well as the Gasometer-City. Security by planning

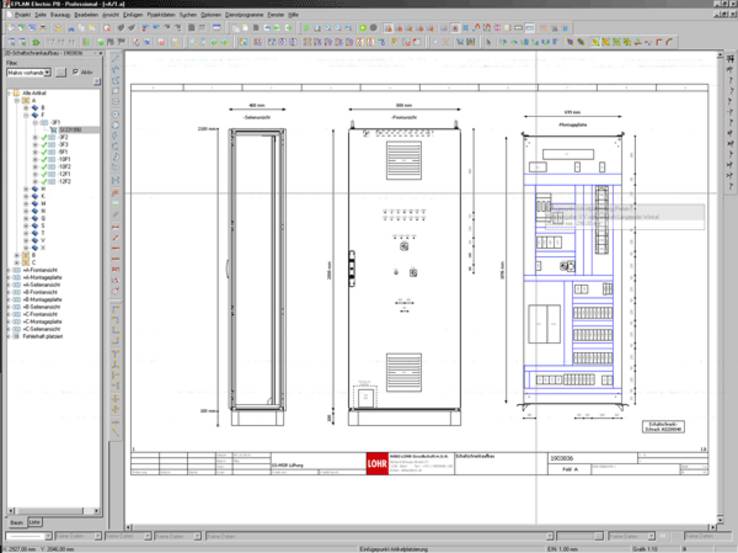

Kulovics is well aware of the fact: "Good planning is a prerequisite for an efficient realization". "And since building systems installations usually have a very long live cycle, the appropriate documentation for service and maintenance is absolutely essential." Back in 1984, when he joined the company, electrical engineering was still done in pen and ink. But the first CAD work station with EPLAN was operational as early as 1989. A four employee CAD/CAE team within the I&C department generates all planning services today on three EPLAN work stations for the otherwise separate technical specialist departments. All software systems have been kept continuously updated and current. When Ing. Joseph Mayerhofer joined the company in the year 2000, EPLAN 5 was the current version. Mayerhofer, who is today's CAD manager states: "When EPLAN Electric P8 became available about three years ago we didn't take the decision for the switch lightly". Since the upgrade did mean a large step anyway, we thoroughly evaluated two alternate products as possible options. "The determining factor for the switch to EPLAN Electric P8 was finally our trust in the expertise of the market leader, our good experiences with support by EPLAN Austria, and the openness and power of the software". Mayerhofer further states: “We only use part of the broad range of options in the CAE tool, but that doesn't have to stay that way, considering the rapid technical development in building services. We already use the PLC interface and import .dxf files from the mechanical CAD system, plus data exchange with Lohr's parts management system have become daily routine." Increasing customer benefits

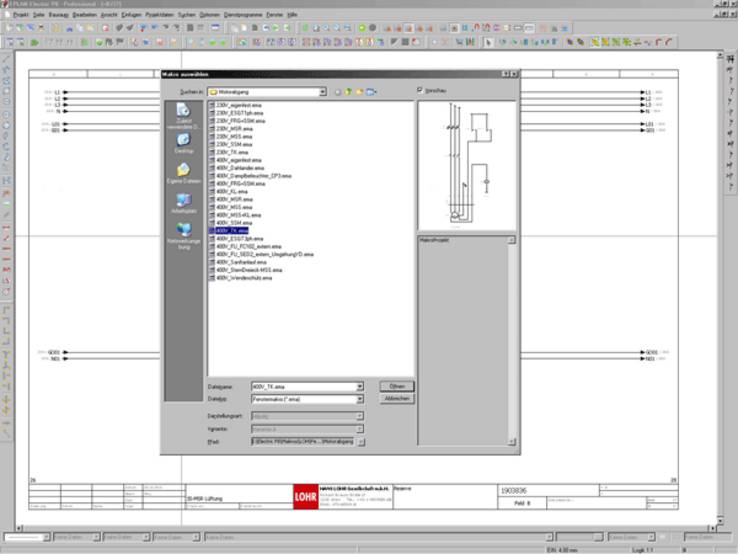

Kulovics considered the improved documentation function as the most important feature of the current version. He knows: "The jump functions in active PDF files facilitate and accelerate error detection and simplify service and maintenance. The quality of layout drawings has also turned out incomparably better in relation to the previous version." Mayerhofer values the improved workflow for design processes. "Using Macros does not only speed up our work, but it also conveys more unified working methods for all employees." "It is now even easier than before to avoid errors, plus the common filing location and flexible collaboration options ensure that knowledge stays in-house, even if an associate should decide to leave." Furthermore, the check runs offered with EPLAN Electric P8 make sure that short-circuits, incorrect assignments of contacts or PLC data points, and duplications of device designations are not possible. This makes it easier for our design engineers to be right on target the first time around with just a little more time invested. The payoff is a greatly reduced rework load and a considerable improvement in efficiency for our design processes. Ready for the future

"The upfront effort of basically reconstructing our data base and as a result increase our productivity was substantial, but the return on our investment realized rather quickly", Kulovics states further. "Complexity and project sizes are continuously increasing, and the energy investment with them. We really welcomed the gain in efficiency EPLAN Electric P8 has to offer." Mayerhofer speaks from experience when he adds: "The operational logic appears to be, after a brief settling in period of course, even more conclusive than in the previous system."

Just like the headquarters of Hans Lohr GmbH building services provider, buildings are not only constructions of stone, concrete, steel, and glass. They are living organisms of electrical and electronic technology.

Ing. Manfred Kulovics, Manger I&C department: "Customers of building services engineering need comprehensive solutions from one mold and across disciplines. That heightens complexity requirements during design."