Direct connection to CAE and ERP

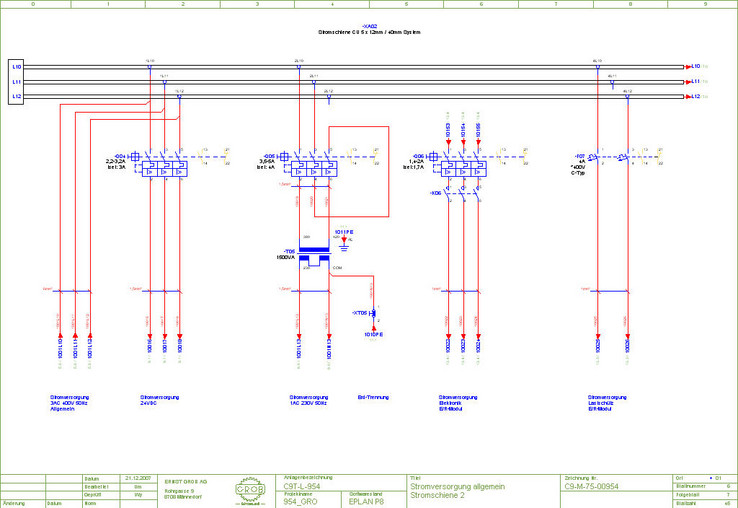

ERNST GROB AG has electrical engineering completely under control: Using EPLAN Electric P8, the designers have formed assemblies which were transferred as components to the EPLAN database.

ERNST GROB AG, located in Männedorf near Zurich, has electrical engineering completely under control: Using EPLAN Electric P8, the designers have formed assemblies which were transferred as components to the EPLAN database. An interface facilitates direct communication with the ERP system, thereby ensuring an automatic continuous flow of information. Every designer involved in the development of automobile transmission components is familiar with the specialized machine tools from ERNST GROB AG located in Männedorf near Zurich, Switzerland. For the past fifty years GROB has concentrated on cold forming without metal removal and therefore offers a practically unrivaled process for manufacturing external and internal gear teeth for transmission shafts, toothed shafts, disk carriers and propeller shaft housing. Innovative process

In accordance with the principle of the impact roll crushing method, the workpiece, which rotates on its own axis during machining, is formed in small individual steps using planetary rolling die arrangements. In this way, highly durable components with a high-quality surface that don't need further finishing can be quickly and eco-nomically manufactured. In addition to transmission components, GROB customers also use these machines to manufacture up to 7 meter long extruder worm shafts for plastics machines as well as pump shafts and toothed shafts used in municipal vehi-cles and aeronautical engineering. Electrical replaces mechanical

Since the end of the 1980s, ERNST GROB AG has used electronic transmissions to synchronize the movements between the work piece and the tool. Another significant development step last year was the use of backlash-free torque motors with a peak torque of 3500 Nm to drive work piece rotation. This means you can do without the previously used indexing discs which made sure that the work piece stopped briefly during machining and then continued to move. Thus, there are always new electrical design tasks that significantly contribute to the increase in performance of the new machine generation. Walter Wymann, head of electrical engineering: "With torque motors, movement can be increased by 25% and machine productivity increases correspondingly." Good connection: CAE & ERP

Since 1986, ERNST GROB AG has used EPLAN software and therefore as "one of the first users" has experienced almost all developments first hand. Electrical engi-neer Urs Marti, who started in electrical design at this time and since then has been an EPLAN user: "We have gotten to know all EPLAN versions and have taken part in all migration steps. The new EPLAN Platform sets new technological standards and is very convenient to use." Traditionally at GROB, there is a connection between EPLAN and the Navision ERP system. Walter Wymann: "The interface between ERP and electrical engineering has paid off. It saves a lot of engineering time thereby avoiding duplication of work for engineers as well as for purchasing and production planning." Systematic migration procedure

When migrating from EPLAN 5 to EPLAN Electric P8 they not only wanted to continue to use this interface, but to improve and extend the functionality. At the same time, the benefits of the new EPLAN Platform should be optimally utilized. Therefore, those in charge at GROB proceeded very systematically with the project. Walter Wymann: "Our objective was to create a database of components that we use as design building blocks." EPLAN 5 did not have such a database solution. There-fore, the designers at GROB first had to enter the data. Urs Marti: "We formed assemblies that are listed as individual parts during design, but are viewed as a whole unit when returned to the ERP system." As a unit or broken down – two views of the same components

Thus an intelligent connection between design on the one hand and purchasing on the other hand is created. The departments use two different views of the same com-ponents: The designer places whole units in the CAD drawing, purchasing sees what needs to be ordered and production can produce the necessary parts. The components are also maintained and updated by the designers because EPLAN Electric P8 is the leading system here. For GROB, one important advantage of the new solution is the direct communication between CAE and ERP: Using ASCII code, a bi-directional connection can be created between the EPLAN database and the Navision database. In the previous version, an add-on module (PMS) was needed for this, which is no longer necessary. Database cleaned up

When the database was created, it was found that many components were no longer used. Wymann: "The life cycle of purchased parts such as controls and motors is continually decreasing. We only transferred those components to the database that are still used in the current machines – that makes it easier to handle and improves performance. If, on the other hand, the components are only needed for documenta-tion or spare parts, then they are left in EPLAN 5, which continues to be used for old data. Walter Wymann: "During the preparation for this work, EPLAN's branch office in Switzerland, Infographics AG, provided us with professional support." Automated documentation in six languages

With respect to multilingual documentation, ERNST GROB AG is also well pre-pared. Walter Wymann: "Initially, we translated the technical terms into three lan-guages at the master data level. For other languages, the translations will be confirmed with the companies and representatives in those countries." The result: After design is completed, automated documentation can be created in the respective language practically at the push of a button, and the new language is automatically available for further projects. Perspective: Increasing significance of engineering

The projects that the designers at ERNST GROB AG are planning for the future require a close connection between fluid engineering and electrical design. In gen-eral, the company is preparing for CAD technologies to play an even bigger role in business processes. Walter Wymann: "The machines are becoming increasingly customized due to requests from our customer. This means that we need to try to standardize the processes - this is where EPLAN Electric P8 plays a significant role. On the other hand, more engineering effort is needed, which, as a specialized com-pany with a lot of technical know-how, we are happy to provide. Speed and precision

In addition to coldrolling machines, ERNST GROB AG produces slotting machines for hollow components that take over the subsequent sheet metal forming process and which are usually delivered in combination with coldrolling machines. One of the special features of these machines, that, for example, punch holes, grooves and mountings in automobile clutch disc carriers while guaranteeing highest precision at high speed, is that hydraulics is not used: They are driven using four electronically coupled CNC axles for each work station. Up to four stamping stations are controlled by one CNC controller.

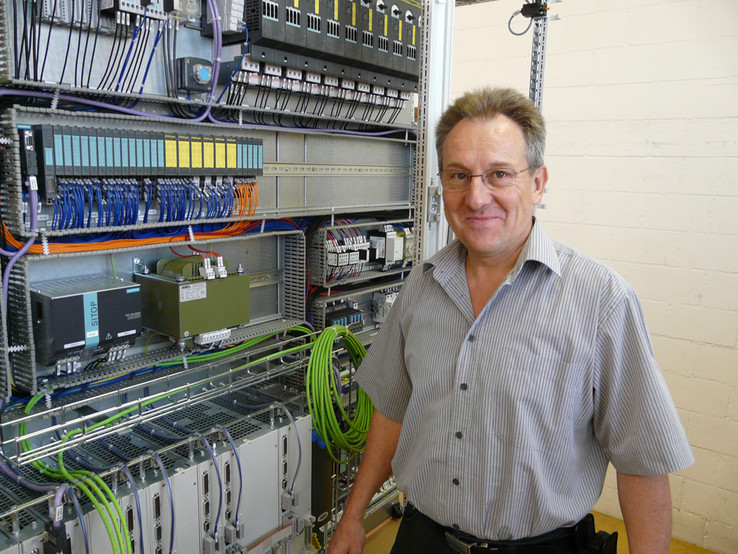

Design manager Walter Wymann in front of an enclosure: The direct connection of the Navision ERP system to the EPLAN Platform has many advantages for ERNST GROB AG.

EPLAN user "at the beginning": Since 1986, electrical engineer Urs Marti has been responsible for schematics at ERNST GROB AG. His more than 20 years of experi-ence is the basis for optimal CAE processes.