Selection of measuring instruments made easy

Instrumentation manufacturer Endress+Hauser uses the EEC as the basis for convenient online configuration.

Instrumentation manufacturer Endress+Hauser uses the EEC (EPLAN Engineering Configuration) as the basis for convenient online configuration. The existing web configurator has been connected with the EEC to generate macros. The web front end has been integrated into the interface of the EPLAN Data Portal. Combined with the portal, the EEC is the right tool for simple online configuration of measuring instruments from a plethora of around 1.2 million possible variations. They measure flow rate, monitor temperature and control pressure and filling level: Instruments by Endress+Hauser are the “eyes and ears” of procedural systems worldwide. This applies for a wide range of industries such as food & beverage production, chemistry, energy production, oil, gas and water and waste water technology.

High-quality measuring technology in 1.2 million variations

The product range is just as wide. The 26 production sites of the Swiss family-run company with its headquarters in Reinach near Basel, which employs almost 13,000 employees worldwide, presides over a product range of around 1.2 million varieties, and its colleagues in sales and service fit out more than two million test stations per year. The very high number of variations comes from the possible combinations of various properties and functions within the individual ranges. As well as the connection size, the user can also select the measurement accuracy, the communication interface and the IP protection type. Other options, for example, include industry-specific certifications, suitability for use in explosive areas and special anti-corrosive equipment.

Target: “One standard to the customer” with online configuration

Of course, the international sales team of Endress+Hauser provide the user with support in making the selection. Engineering and planning are in great demand because users increasingly want individual system solutions. But frequently, customers use the online configuration to selection and ordering as well as to download documentation, drawings and certificates. In the past, there was no uniform standard here. Philipp Rumler, programme manager at Endress+Hauser Consult AG says, “Within our company, the individual business units and production sites have a very extensive order code, which is sometimes structured differently, due to the large variety of customer requirements from different industries. However, our aim was to standardise the arising data so that the selection of instruments in the online configurator is always in line with the same standard and, above all, created in an automated manner – irrespective of the measuring principle, range or location.”

Creative combination of design tools

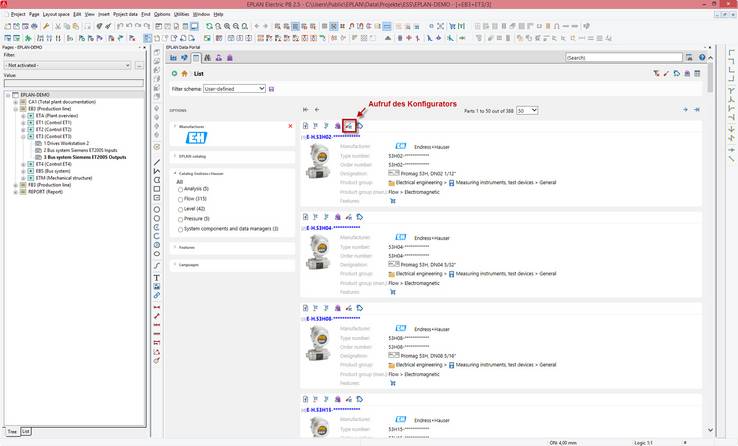

Endress+Hauser Consult AG turned to EPLAN with this request, and together they developed a concept to link the in-house configurator to the EEC (“EPLAN Engineering Configuration”) and integrate it into the EPLAN Data Portal. This might be surprising at first glance, because these two tools are used in design and development in many cases. Normally, machinery, systems and components are functionally described in the EEC and macros (partial circuits) are generated through the control system into a consistent schematic, i.e. intelligently merged. This considerably minimises the time needed for the electrotechnical design. On the other hand, the design engineer traditionally uses the EPLAN Data Portal as a web-based instrument data platform to efficiently compile his or her article master data. Technical data and drawings of components from leading manufacturers are filed here, which the design engineer integrates into the design of his or her machinery / plant. This includes drive elements such as motors and converters, but also measuring instruments such as those from Endress+Hauser.

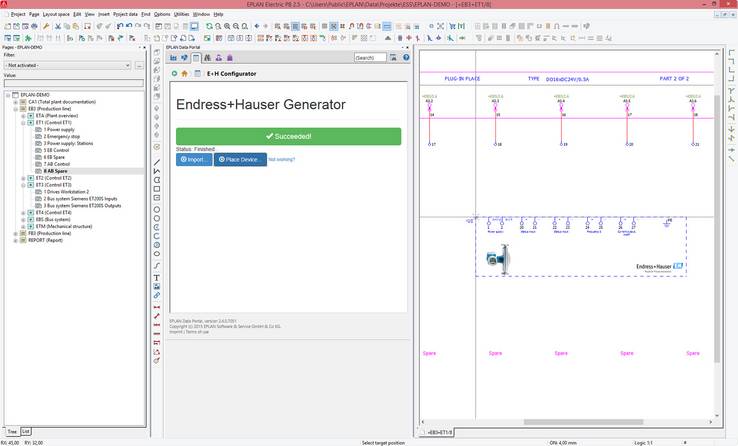

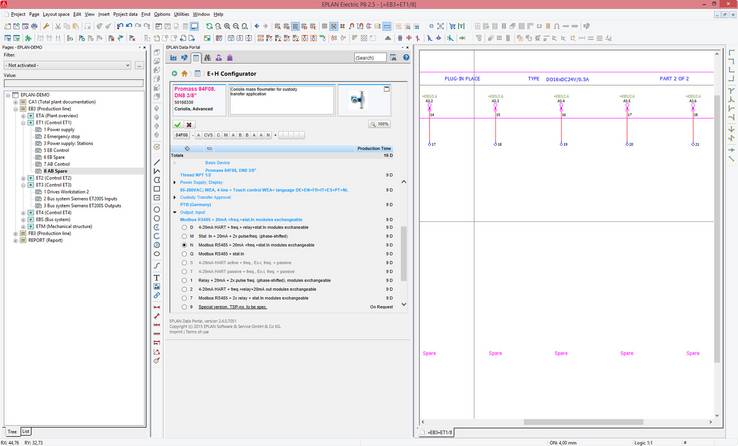

Two ways lead to the objective

In many mechanical engineering companies, the EEC and the EPLAN Data Portal normally work upstream in design and development. At Endress+Hauser, both systems are used in combination with the existing online configurator for the user. There are two ways to do this. The currently available and more deeply integrated way is directly through the EPLAN platform. By linking the online configurator with the underlying EEC to the EPLAN Data Portal, the possibilities of the configurator are available to the more than 85,000 registered users directly in the design environment. By selecting a measuring principle (measuring instrument) in the EPLAN Data Portal, the configurator is initiated – embedded in the data portal environment. This is where the user can put together “his or her” individual measuring instrument. During entry of the configuration, the underlying EEC automatically combines the filed data and generates the right macro “on the fly”, which can now be adopted directly into the schematic. And in the background, all the commercial data and technical documents are also adopted into the EPLAN item management. This makes the subsequent ordering process considerably simpler and helps to replace the broken instrument and quickly get the machine started again in case of repairs. Next year, the EPLAN data will also be available via the Endress+Hauser configurator. If the user is on the Endress+Hauser website, he or she uses the online configurator as before. The small, but effective difference: At the end of the configuration, he receives a complete EPLAN macro of the required measuring instrument again, which is ready for download. The user will not notice this because the interface of the configurator was developed by Endress+Hauser itself and has the company’s corporate design.

Simple configuration, smooth processing of data

The benefit of offering this new type of product configuration for Endress+Hauser clients is clear. The client can configure “his or her” instrument in a few steps, can order it directly if required and receives all the required data, drawings and documents at the touch of a button. Philipp Rumler says, “The design engineer can access an entire data package and integrate this directly into his design – for example an assembly drawing, which he can edit directly with EPLAN Electric P8. He can also request the data, including “spec sheets” and manuals, as PDF files and continue to work on them with other CAE systems.” In this way, the user benefits from the data being created “live” in the EEC or EPLAN Data Portal, meaning it is always up-to-date.

Good support from EPLAN Consulting

This new type of configuration on the basis of a “turnkey”, individual combination of EEC and the EPLAN Data Portal makes the design engineer’s work easier and enables a selection of instruments that spans the product groups but is always in line with the same schema. But this schema and the underlying structure first had to be developed. Philipp Rumler says, “We worked intensively with the optimal structuring and were supported very well by EPLAN Consulting. We developed a separate model with its own specific features and macros for each measuring task.” Who uses this tool? According to initial experiences from Endress+Hauser, the user group is very heterogeneous: “Both global corporations and medium-sized users work intensively with the configurator. The “greats”, who have internal standards for their measuring instruments and test points, mainly use the opportunity to download drawings and documents. Smaller companies and planners configure the desired instruments, and our international distribution companies also work with the configurator when they are planning customer-specific projects.”

Benefits for the instrument manufacturer too

It is even possible to access documents for older instruments, as Endress+Hauser has linked a “product container” into the EEC, in which older versions are saved. The configurator also accesses these. This is a future-focussed function: At Endress+Hauser, the trend of users wanting support and documentation of instruments from the manufacturer throughout the entire life span can be seen. The solution is an ideal platform for this service. In addition, the distribution team can recognise which instrument variations are currently in particular demand using the tracking function of the configurator. And as the electrical design engineers at Endress+Hauser work with EPLAN Electric P8, they have a central platform which extends from design through to distribution. Philipp Rumler says, “The system works without media disruptions and without duplicate entries. All data is always up-to-date and it is only inspected at one place.”

Summary: Simple planning – Access to all required data

As a result, Endress+Hauser has developed a solution on the basis of EEC, which simplifies internal procedures and also saves costs. But the advantages that arise from a customer point of view are more important to the company. Philipp Rumler says, “Our customers should save time when selecting and planning the measuring instruments, if they do not commission us to do this, and should have easy access to all the data they need. This was our central objective and we have achieved it.” And this is more important than simplifying internal procedures, as the top principle at Endress+Hauser is: The customer always takes precedence.