One item of hardware for a multitude of machine variants

Eggersmann modularises electrical engineering for its mobile machinery

Eggersmann GmbH manufactures mobile recycling machinery and has systematically modularised electrical engineering for its vehicles. The main control cabinet has been enhanced through an efficient wire-harness concept with interfaces being defined for each module. This enables “plug & play” modules to be produced for the machines. Using interfaces, different options are available from wire harnesses. The core “tools” for this change in approach are the EPLAN Harness proD and EPLAN Cogineer.

Whoever has composted garden waste knows that it occasionally needs turning with a spade. Only then can the material decompose evenly and produce high-quality soil. This task is even more important in large-scale systems and is performed by turners which manoeuvre on caterpillar tracks mixing up windrow heaps using a rotor to move the lower layers to the top and vice versa. This is a niche segment in mobile machinery in which Eggersmann GmbH, based in Wardenburg/Oldenburg, has established an excellent market position under the BACKHUS brand. The company is a world leader for turner technology and has so far constructed around 1300 machines which are being used in 78 countries around the world. In 2012, BACKHUS became part of the Eggersmann group who specialise in manufacturing mobile and stationary machines for shredding and recovery and were therefore an ideal match for the BACKHUS turner professionals. Jens Brinkmann, head of electrical engineering at Eggersmann GmbH: “The Eggersmann group, as a full liner, now offers a complete range of recycling technology extending through to the construction of entire composting and recovery facilities.” In a well structured and “tidy” production hall, employees manufacture, to order, a wide spectrum of machinery – mainly personnel operated turners with cockpits offering an extensive range of options from which users can select, e.g. different chassis, moveable cockpits, remote controlled hose trolleys for irrigating compost etc. BACKHUS also provides a system for automated turning: the “Lane Turner” operates in an enclosed, driverless system.

Systematic modularisation in engineering

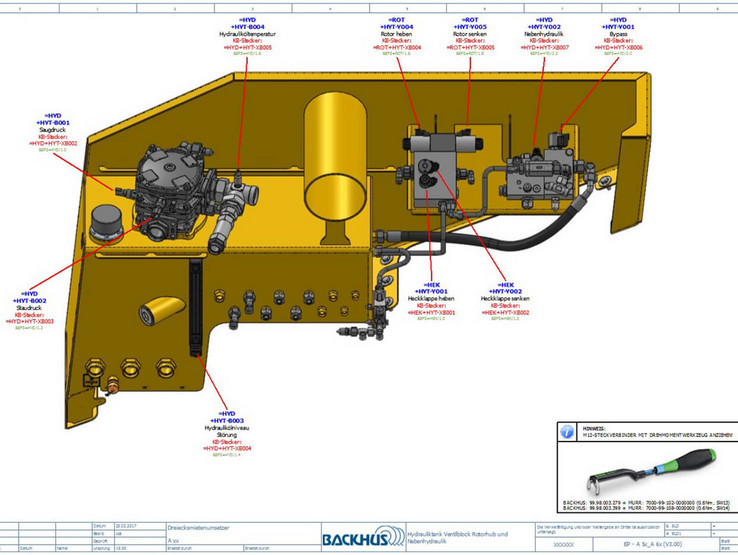

Electrical and electronic engineering are playing a major – and growing – role in the operation of BACKHUS turners. For example, vehicles can also be operated via a “virtual cockpit” which also enables fast diagnostics in the event of irregularities. Furthermore, the machine’s tool, the rotor, is equipped with sensors for recording data, e.g. rotation speeds and oil temperatures. A high number of options and variants exist both in electrical design – which takes place using EPLAN Electric P8 – and in the machines themselves, so there is a clear need for simplification. Jens Brinkmann therefore opted for systematic modularisation which he implemented first in the BACKHUS A-series. “We create modules for the electrical components of each functional unit, e.g. the rotor, cockpit, hydraulic tank, basic framework and engine unit. These are then connected via interfaces.” In each project, the electrical schematics for the individual modules are merged together into a central overall schematic. The same applies for the hydraulic plans which are created using EPLAN Fluid. To simplify electrical assembly, plug-in connectors, requiring no tools for assembly, are defined as interfaces designed to accommodate a maximum range of components. Jens Brinkmann: “Modularisation has optimised workflows with modules being prepared and manufactured and then installed on the machines. This significantly shortens assembly times.” If queries should arise, electrical engineering documentation for internal use is created using EPLAN. These can then be visualised during production and utilised to an even greater extent by service personnel. A consultancy team from EPLAN supported the process and worked intensively with the company on product structuring.

Standardisation and structuring – the key to efficiency

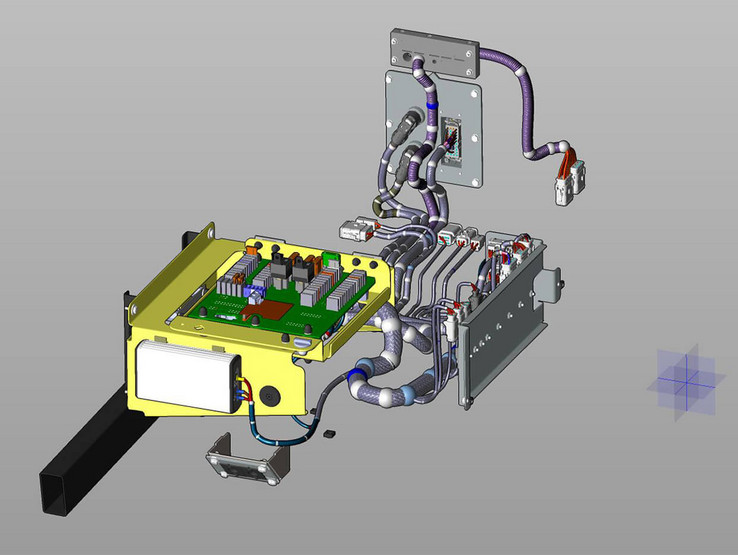

Jens Brinkmann and his team also re-structured schematics from being location-based to being function-based. There are clear benefits from systematically modularising, standardising and structuring electrical design so the same process is being applied to other machines being manufactured by Eggersmann GmbH in addition to the BACKHUS compost turners . This has resulted in a control cabinet being used equipped with same hardware for shredding and separation machines. The process of modularisation and standardisation continues to be implemented across the electrical engineering infrastructure. Jens Brinkmann: “The hardware in control cabinets is identical for every machine. The specific functions and options for a turner are provided by the wire harness inside the cabinet. The harness is individually produced and connected using a standard plug.”

Precision cable routing – using EPLAN Harness proD

The wire harnesses are designed using EPLAN Harness proD – and have been done so for almost 3 years. The 3D/2D software creates a wire harness and its routing tracks on the basis of a STEP file from mechanical design (in this case Solidworks). Jens Brinkmann: “It fits perfectly every time and also saves lots of time.” An external provider fabricates the wire harness according to specifications from EPLAN Harness proD. Eggersmann has meanwhile begun to use this principle to also design and route cabling within the control cabinets. Plug-in circuit boards are also being used thereby further simplifying electrical assembly.

Selection using EPLAN Cogineer

The four electrical designers have recently begun using EPLAN Cogineer – a brand-new tool for automated schematic generation based on mechatronics rule sets. Its operation is very simple. On a project sheet, designers click the options required by the user, e.g. camera, electrically operated mirror, irrigation module. The schematic is then generated automatically in the background. The software is easy to use and gives designers extra time for real engineering tasks.

Cross-series modularisation

Eggersmann GmbH has already implemented modularisation and standardisation for its turners and shredding machines. The benefits are plain to see especially in time gains, the elimination of duplicate tasks and consistency in electrical-design quality. The company has therefore taken a further step by defining common electrical components, such as control and modules, which can be used in different product series. Jens Brinkmann: “We use the same item of hardware in different turners and shredders, and are planning to do the same for trammel screens. The differences and variances are accounted for by the wire harness.” Giving responsibility to the Wardenburg site for the electrical engineering of other Eggersmann brands and products has resulted in additional work which needed to be paid for by increased efficiency. “We have achieved this through standardisation and by changing our approach. We began with Eggersmann mobile shredding machines and are continuing with Terra Select trommel screens.” EPLAN tools for modularisation and standardisation – in particular EPLAN Harness proD and EPLAN Cogineer – mean the Eggersmann engineers are optimally equipped for the changes. “Implementing Cogineer has enabled us to work with just one macro project – including for revisions – whereas previously we had multiple basic plans for the different machines. This has reduced the effort required for revisions to a fraction of what it was”, said Jens Brinkmann. Eggersmann is also going through a process of change concerning product data management. Cideon, an EPLAN affiliate company, has supplied the Pro.File PDM solution which is being installed across the whole group. Design, engineering and product data management are therefore ideally prepared for the challenge of delivering innovative recycling technology.