Operations and Service

Do It More Reliably with Our Smart, Global Service

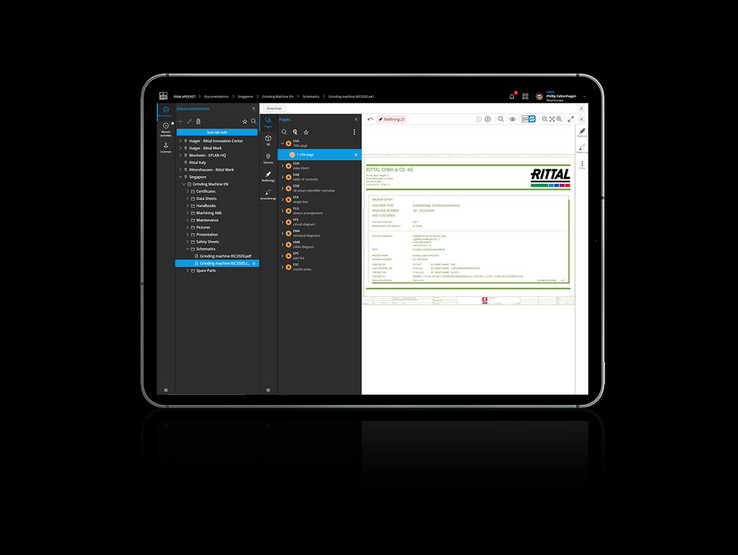

Plants and machines must continue to function safely and reliably over the long term well after commissioning. It’s simply a prerequisite for efficient and high-performance production. That’s why many Rittal data enclosures and components such as climate control units are now equipped with sensors that generate a continuous flow of data. This data helps make predictive maintenance a reality right now. You also reap the benefits of consistent engineering data when service or maintenance work is needed when a product is in operation: EPLAN’s cloud-based solutions enable you to keep an eye on the status of your project data over the long term, no matter where you are in the world. Furthermore, adjustments made to the product can be directly noted and also flow into the digital twin – for a continuously digitised value chain, from engineering to operations.

Operations

Data access via cloud solutions is possible at any time and from anywhere – even on mobile devices. This is of great benefit for the maintenance and repair of the enclosure.

Service

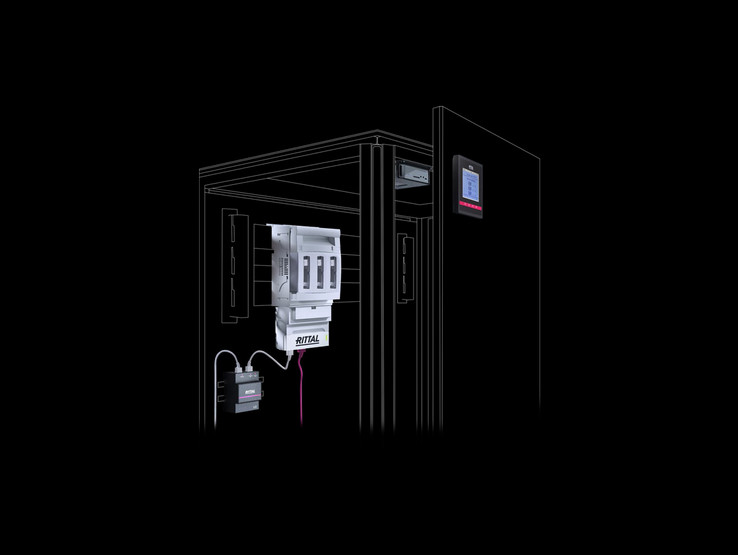

The enclosure and or the cooling unit itself can also generate and send data, for example current status information, temperatures, maintenance data etc. This is made possible by components with an IoT interface and hardware such as the Rittal IoT Interface, which collects data and transmits it to overarching systems. When data along the value chain are digitized, service and operations can benefit as well.