Even greater value and productivity in switchgear construction

By taking over Kiesling Maschinentechnik, Rittal International has significantly expanded its expertise in the manufacture of switchgear and panel building.

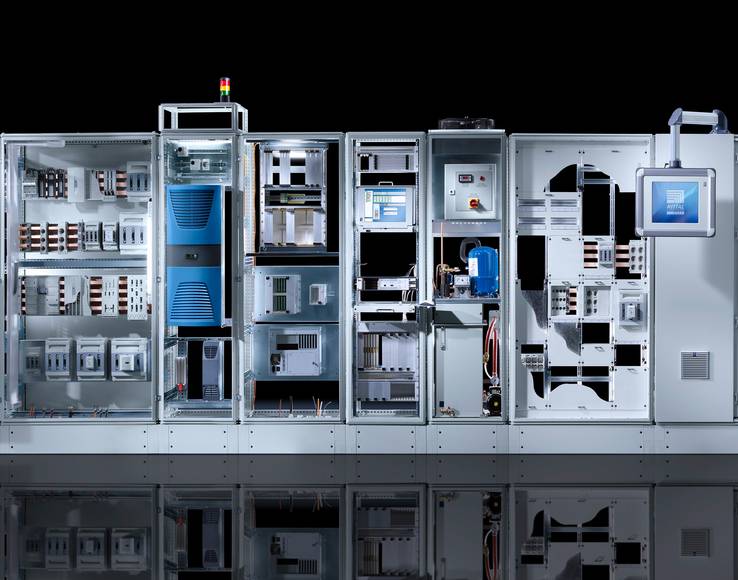

By taking over Kiesling Maschinentechnik, Rittal International has significantly expanded its expertise in the manufacture of switchgear and panel building. Now, the three companies of Rittal, EPLAN, and Kiesling now form a unique global service network in this sector. Customers will thus benefit in future from continuous solution competence, as well from improved productivity along the entire value creation chain in enclosure and switchgear construction: from engineering through to robotic wiring. Hanover, 8 April 2013. With the platform from EPLAN (a leading provider of software-based engineering solutions), the complete range of enclosures from Rittal (world leader in enclosure system technology), and automation solutions from Kiesling Maschinentechnik (technology leader in enclosure processing), Rittal International possesses integrated solution expertise in the field of switchgear and panel building. With its future-oriented automation solutions for switchgear manufacture, Kiesling Maschinentechnik brings a new innovation potential to the group, which customers can benefit from. For example, the mechanical engineering company has many years of technological expertise in the mechanical processing of enclosures. The latest technological breakthrough is the “Averex” robotic wiring system, which will replace the time-consuming manual wiring of mounting plates in future, and which will provide automatically generated, standard and security-oriented connections between the resources on the mounting plate. From engineering to robotic wiring

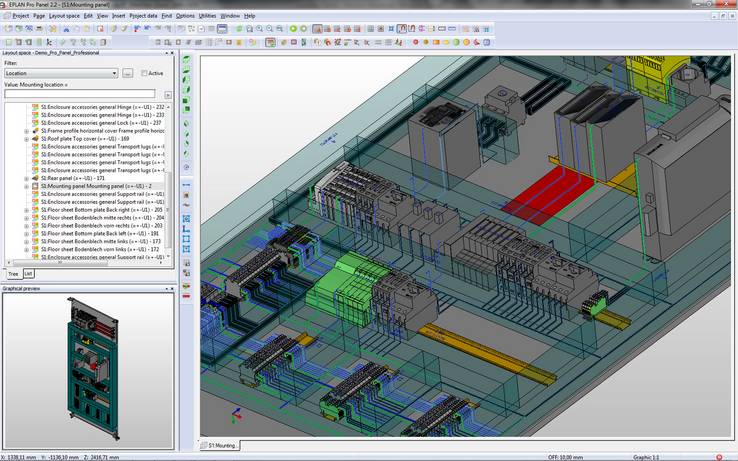

Enclosure system constructors can configure an enclosure solution using data from the EPLAN Data Portal, the electrical circuit diagram or from the fluidic detail and hardware engineering and the system knowledge on enclosure components and accessories from Rittal stored in the EPLAN platform or in EPLAN Engineering Center. With EPLAN Pro Panel they can easily and convenient place all the specified resources and accessories in 3D. Information on mounting holes, hole threads or openings is thus generated automatically or added interactively on demand. Based on the 3D enclosure prototype and the connection information from the circuit diagram, EPLAN Pro Panel determines the optimal wiring distances and the lengths needed for the wires and cables. All the information required for the document management, machining or assembly and installation of the wires is provided by EPLAN and issued in the form of order and parts lists, manufacturing, and assembly drawings or as machine programs. Once the design complies with the technical specifications, “real” enclosure system manufacture with components from the “Rittal – The System.” range can begin. This is followed by the mechanical processing of the enclosure or housing and the mounting plate with processing machinery from Kiesling. The wiring data provided by EPLAN, as well as the information from the 3D model on components and their position on the mounting plate is passed to the Kiesling “Averex” wiring robot via a specially developed machine interface. With this information, the robot verifies and checks the manual construction of the mounting plate and then independently and automatically wires the components. A change of wire when colour or cross-sections are changed is also included. This considerably speeds up the process of wiring, which would otherwise be performed manually; time and cost savings as well as a seamless workflow are the success factors. Customers will thus benefit in future from continuous solution competence, as well from improved productivity along the entire value added chain in enclosure and switchgear construction: from concept development in electrical and fluid engineering and technological implementation via material logistics and mechanical processing down to installation – including the robotic wiring of control components in the enclosure. Rittal GmbH & Co. KG, April 2013

Based on the 3D enclosure prototype and the connection information from the circuit diagram, EPLAN Pro Panel determines the optimal wiring distances and the lengths needed for the wires and cables.